DIN vs AS vs JIS Rail Profiles: What are they?

Choosing the right rail profile for your crane system is critical to ensuring long-term performance, safety, and compliance. In Australia, three major standards dominate the conversation: DIN (Germany), AS (Australia), and JIS (Japan). Each has unique characteristics, and the right choice depends on your application, environment, and sourcing strategy.

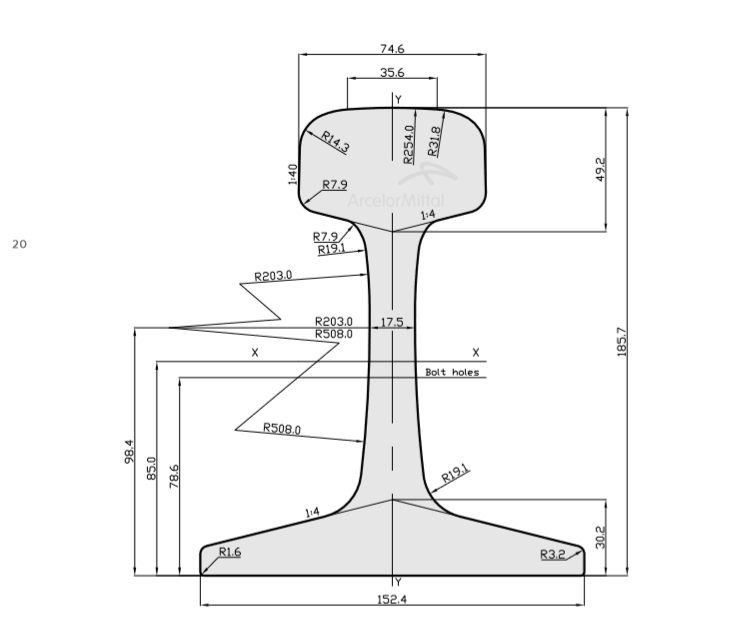

DIN Rail Profiles (DIN 536)

Origin: German Institute for Standardization

Common Types: A45, A55, A65, A75, A100, A120 & A150

Applications:

- Widely used in overhead crane runways, port terminals, and heavy industrial settings

- Known for high load capacity

Advantages:

- Excellent for high-speed, high-load crane systems

- Compatible with adjustable clip systems

- Global availability

Considerations:

- Imported rails can have longer lead times

AS Rail Profiles (Australian Standard)

Origin: Standards Australia

Common Types: 41kg, 47kg, 50kg, 53kg, 60kg, 68kg

Applications:

- Used extensively in mining, freight, and crane rail systems across Australia

- Manufactured in Whyalla, Australia’s only domestic rail producer

Advantages:

- Locally available with shorter lead times

- Designed for Australian conditions including extreme temperatures and heavy haul operations

- Proven performance in head-hardened applications for fatigue resistance

JIS Rail Profiles

Origin: Japanese Industrial Standards

Common Types: 6kg to 30kg (light rail)

Applications:

- Common in light rail, crane rail systems and tramways across Asia

Advantages:

- High-quality steel with uniform hardness across the rail

- Suitable for light-duty cranes and automated systems

Considerations:

- Less common in Australia and may require special ordering

- Not ideal for heavy-duty or mining applications

Which Is Right for Your Crane?

| Criteria | DIN | AS | JIS |

| Heavy Load Capacity | ✓ | ✓ | – |

| Local Availability in Australia | – | ✓ | – |

| Precision Alignment | ✓ | ✓ | ✓ |

| Fatigue Resistance | ✓ | ✓ | ✓ |

| Best for Light-Duty Cranes | – | – | ✓ |

Final Recommendation

If you’re operating in Australia and need reliable, compliant, and locally available crane rail, AS rail profiles from Whyalla are the most practical and strategic choice. They are the only rail profiles manufactured domestically, ensuring supply chain security and alignment with Australian standards.

For specialised applications or international projects, DIN profiles offer engineering precision and global compatibility, while JIS profiles are best suited for light-duty or automated crane systems.

More Posts

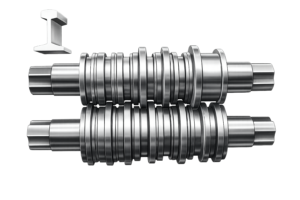

How is rail manufactured? Let’s look at the rail rolling process

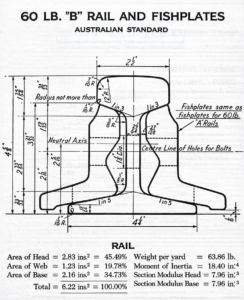

When maintaining or upgrading industrial tracks, slipways, or crane runways, a major challenge is sourcing replacements for rail sections that are no longer manufactured. This includes BHP 60 lb B rail and the later 31 kg rail profile. Both have been out of production for decades, which means operators today need a reliable, modern alternative.

How should I replace BHP 60lb Rail or 31kg Rail?

When maintaining or upgrading industrial tracks, slipways, or crane runways, a major challenge is sourcing replacements for rail sections that are no longer manufactured. This includes BHP 60 lb B rail and the later 31 kg rail profile. Both have been out of production for decades, which means operators today need a reliable, modern alternative.

What is Block Rail?

Block Rail, or flat bar crane rail, is a simple yet essential component in crane rail systems throughout Australia. It supports smooth reliable travel for trolleys and overhead cranes in workshops warehouses and industrial facilities.

What you need to know about branded rail clips!

At Inform Rail, we regularly review drawings that specify an existing rail clip, a clip that’s no longer manufactured, or the two classic words: “or equivalent.”

But what does it really mean for you when pricing a project, replacing rail clips or designing a new system?