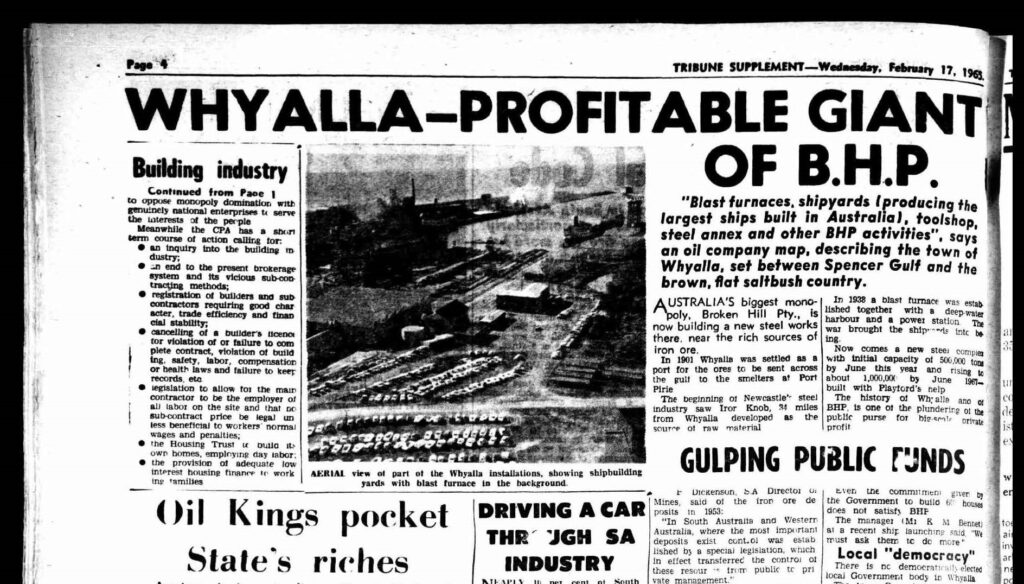

Whyalla’s Origins: Building Australia’s Rail Capability

Whyalla has long stood at the centre of Australia’s rail infrastructure story. From its early days under BHP to its current role as the nation’s only domestic producer of steel rail, Whyalla’s contribution to crane & rail systems is unmatched in scale, quality, and strategic importance.

The foundation of domestic rail production began in 1915 with the BHP Newcastle Steelworks, but it was Whyalla that evolved into the country’s rail manufacturing powerhouse. By the 1970s, BHP’s Whyalla plant had developed head-hardened rail technology to meet the demands of heavy haul mining operations in the Pilbara and coal regions of Queensland and New South Wales.

These rails were engineered to withstand:

- High axle loads

- Intense cyclic fatigue

- Harsh environmental conditions

Whyalla’s head-hardened rail technology was so effective it was licensed internationally, including to American manufacturers, along with proprietary welding techniques.

Whyalla and Crane Rail Systems

Rail systems require precision, durability, and fatigue resistance. Whyalla’s rail products—particularly the Australian Standard 41kg to 68kg profiles—are ideally suited for:

- Overhead crane runways

- Container terminals

- Heavy fabrication yards

- Mining and port infrastructure

The integration of soft mounting systems, resilient pads, and advanced fastening solutions such as the Wilclip fastener (developed by BHP) further enhances performance by reducing vibration, wear, and fretting corrosion.

Sovereign Supply: Whyalla’s Strategic Role

Today, Whyalla is one of only two steelworks remaining in Australia and the only domestic producer of steel rail. It supplies:

- 75% of Australia’s structural steel

- Unique rail profiles manufactured to Australian standards

- Critical infrastructure for mining, freight, passenger and crane rail systems

There is no alternative domestic source for Australian-standard rail. If you are sourcing crane rail in Australia, Whyalla is the only supplier capable of meeting national specifications with local production. This ensures:

- Reduced lead times

- Proven performance in Australian conditions

- Compliance with AS standards and compatibility with DIN and JIS profiles

Why This Matters for Crane Rail Buyers

Whether you’re installing a new crane runway or upgrading an aging system, Whyalla rail offers unmatched reliability, fatigue resistance, and long-term value. Its legacy is embedded in the very tracks that support Australia’s industrial economy.

More Posts

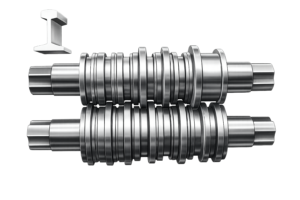

How is rail manufactured? Let’s look at the rail rolling process

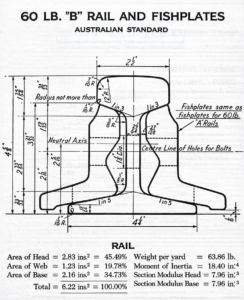

When maintaining or upgrading industrial tracks, slipways, or crane runways, a major challenge is sourcing replacements for rail sections that are no longer manufactured. This includes BHP 60 lb B rail and the later 31 kg rail profile. Both have been out of production for decades, which means operators today need a reliable, modern alternative.

How should I replace BHP 60lb Rail or 31kg Rail?

When maintaining or upgrading industrial tracks, slipways, or crane runways, a major challenge is sourcing replacements for rail sections that are no longer manufactured. This includes BHP 60 lb B rail and the later 31 kg rail profile. Both have been out of production for decades, which means operators today need a reliable, modern alternative.

What is Block Rail?

Block Rail, or flat bar crane rail, is a simple yet essential component in crane rail systems throughout Australia. It supports smooth reliable travel for trolleys and overhead cranes in workshops warehouses and industrial facilities.

What you need to know about branded rail clips!

At Inform Rail, we regularly review drawings that specify an existing rail clip, a clip that’s no longer manufactured, or the two classic words: “or equivalent.”

But what does it really mean for you when pricing a project, replacing rail clips or designing a new system?