What is Block Rail? (Flat Bar Crane Rail)

Block Rail, or flat bar crane rail, is a simple yet essential component in crane rail systems throughout Australia. It supports smooth reliable travel for trolleys and overhead cranes in workshops warehouses and industrial facilities.

The design is straightforward because it is shaped as a solid block. This simplicity gives it excellent weldability and reduces the time needed for wheels to settle into smooth operation. Rounded edges help wheelsets move quietly with less vibration and lower friction which increases service life for both the wheel and the rail.

Block Rail is often discussed alongside conventional rail and square bar rail which differ in shape and purpose.

Block and square bar profiles are typically expressed by width and thickness.

Block rail is used in gantry work particularly in outdoor locations across Australia where load stability is important. Both block rail and square bar rails have the benefit of not needing fishplates since they can be welded directly with standard welding rods which creates a smooth continuous running surface and speeds up installation with fewer components.

Who do you install block rail?

As always, with all types of crane rail, planning is vital before installing. Important considerations include crane capacity span runway length and site conditions such as exposure to weather or corrosive environments. These factors determine the most suitable rail type and the ideal installation technique.

When installing a fixed rail, like block rail, there are two primary approaches.

One approach is welding the rail straight onto the top flange of the crane girder. This is often used for very light duty systems although it offers no room for adjustment. High accuracy during fabrication is essential to avoid misalignment. Incorrect welding procedures may distort the girder which is difficult to correct once completed.

The second approach is bolting the rail through the base directly onto the girder flange. This avoids welding related distortion yet still provides no lateral adjustment and no capacity for the rail to float along its length.

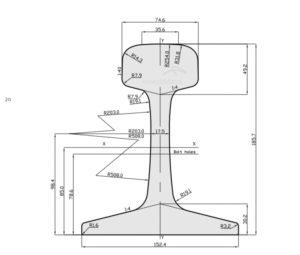

How is block rail different to conventional rail?

Conventional rail (crane rail and standard rail has a shaped profile with a head, a web and a base. This profile is specifically engineered for cranes that experience higher loads or require better tracking under side forces. The shape helps centre the wheel and maintain alignment under more demanding conditions. These rails are usually bolted or clipped rather than welded because they need the ability to float slightly along the girder. This movement absorbs expansion movement vibration and load transfer which is essential in medium or heavy duty applications.

Another key difference is adjustability. Block Rail when welded directly to the girder flange has no lateral or vertical adjustment. What you weld is what you get. Conventional crane rail allows the use of clips and pads which means the installer can fine tune alignment. This is vital for longer crane runways where thermal expansion or small fabrication tolerances would otherwise cause misalignment.

Why choose block rail?

Block Rail remains a highly effective choice for many Australian workshops factories and warehouse operations seeking dependable guided motion without unnecessary complexity. It delivers quiet operation smooth travel strong weldability. Its uncomplicated shape simplifies installation. It provides wheelsets with a stable running surface that reduces wear which increases the lifespan of the entire crane or trolley system.

For businesses across Australia looking to enhance productivity with a cost effective long lasting solution Block Rail continues to be one of the most practical and reliable options available.

More Posts

DIN vs AS vs JIS Rail Profiles: What are they?

When sourcing crane rail for industrial applications, whether for overhead cranes, port terminals or fabrication yards, understanding where your rail is made is essential. The origin of your rail affects not only quality and compliance but also availability, lead times and long-term performance.