How is rail manufactured? Let's look at the rail rolling process

Rails are the backbone of every rail network. Designed to carry extreme loads over millions of wheel passes, rail must be manufactured with a high degree of precision to ensure safety, durability and long service life.

From heating and rolling through to straightening and inspection, the rail manufacturing process combines metallurgy, mechanical engineering and strict quality control. This article explains how rail is manufactured, step by step, and why each stage is critical to performance in service.

In this article, “rail” refers to rolled steel rail used in rail infrastructure applications.

Starting Point: Blooms and Rail Steel

Rail manufacturing begins with blooms which are large, semi‑finished steel sections with a square or rectangular cross‑section. Because rail is a heavy section, it can often be rolled directly from blooms without intermediate reheating, provided sufficient temperature is maintained during rolling.

Rail Steel Composition

Rail steel is designed to be harder and more wear‑resistant than standard structural steel. Typical rail steel contains:

- Carbon: approximately 0.45–0.60%

- Manganese: approximately 0.70–1.20%

This chemistry provides the strength, hardness, and fatigue resistance required to withstand repeated wheel loads and long‑term wear on track.

Reheating the Bloom

Before rolling, blooms must be heated evenly to the correct rolling temperature. Unlike ingots, blooms rely entirely on external heating, which makes temperature control particularly important. Uneven heating can lead to distortion, cracking, or poor final rail geometry.

Firstly, what are the types of reheating furnaces?

Continuous Reheating Furnaces

Continuous furnaces are typically used when blooms are charged cold. Blooms move progressively through the furnace against the flow of hot gases, allowing gradual and uniform heating. This reduces thermal shock and helps ensure consistent behaviour in the rolling mill.

In‑and‑Out Furnaces

Where blooms arrive hot from a cogging mill, in‑and‑out furnaces are used to quickly raise the temperature before rolling. Blooms are placed directly into the hottest zone and removed as soon as rolling temperature is achieved, minimising delays and heat loss. Correct reheating is critical because:

- Overheated rail can slip in the rolls

- Underheated rail resists deformation and can damage equipment

Let’s explain the rail rolling process

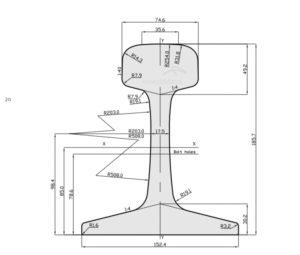

Rail rolling is significantly more complex than rolling simple shapes such as bars or billets. As we already know, rail consists of three distinct parts:

- Head – the running surface for wheels

- Web – the vertical section connecting head and foot

- Foot – the base that distributes load into sleepers and ballast

Each part must receive a balanced amount of mechanical work during rolling to ensure uniform mechanical properties throughout the rail section.

Grooved rolls and pass design

Rails are rolled using grooved rolls, with the rail typically lying on its side so it can pass in and out of the roll grooves. Because the rail profile cannot be re‑entrant, careful roll design is essential.

Closed pass rolling

To prevent excess metal flowing out between the rolls and forming fins, much of rail rolling is carried out in closed passes. In a closed pass, the groove is cut into one roll while the opposing roll acts as a closer. Closed passes:

- Improve dimensional accuracy

- Reduce surface defects

- Provide better control of metal flow

Roughing and finishing Passes

Rail rolling is carried out in a sequence of roughing and finishing passes, often using a combination of two‑high and three‑high rolling mills.

- Early passes focus on forming the foot of the rail

- Intermediate passes develop the web and head

- Final passes bring the rail to its exact finished profile

Because rail steel contains more carbon than mild steel, less reduction is possible per pass, making pass design and temperature control especially important.

To maintain accuracy and extend roll life, the final pass is often duplicated, sharing wear between two identical grooves.

Heat Control and Rolling Defects

Thin sections of a rail cool faster than thick sections. If parts of the rail, particularly the foot, cool too quickly:

- Cracking can occur in later passes

- Final dimensions may fall outside tolerance due to stretching

Maintaining sufficient and uniform temperature throughout rolling is essential.

Common Rail Rolling Defects

Potential rolling defects include:

- Fins – thin metal projections at roll joints

- Laps – fins that have been rolled back into the surface

- Buckles and kinks – caused by poor roll alignment or guard setting

- Roll marks – due to worn or damaged rolls

- Bad section – caused by poor heating, roll wear, or incorrect roll design

Preventing these defects requires careful control of roll condition, mill setup, and temperature at every stage.

Cutting, Cooling, and Straightening

After rolling, rail is cut to length using a hot saw, which avoids distorting the rail profile. Ends are cropped as required to remove any sections that may be out of tolerance.

Controlled Cooling

Rails are placed on cooling banks and allowed to cool under controlled conditions. Often, rails are cooled upside down to counteract bending caused by uneven cooling between the head, web, and foot.

Cooling must be protected from excessive draughts or uneven airflow, which can harden the rail surface and increase brittleness.

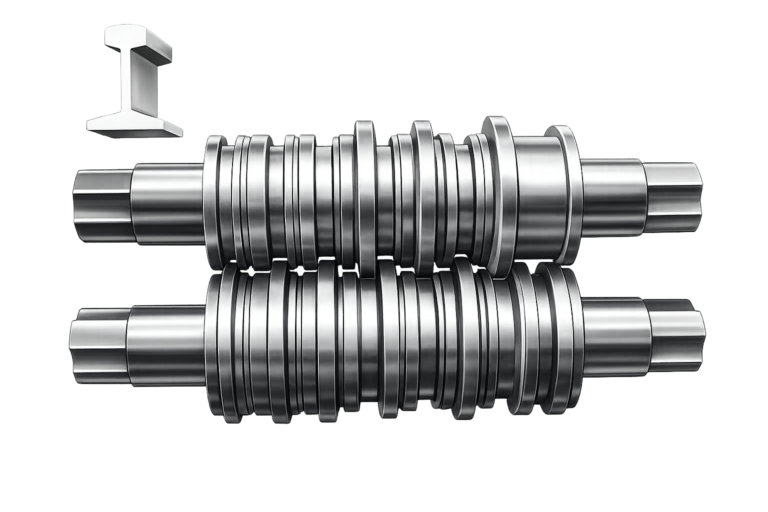

Roller Levelling

Once cool, rails pass through a roller leveller, which progressively bends the rail up and down until it exits perfectly straight and within alignment tolerances.

Inspection and Testing

Because rail is a critical safety component, inspection and testing are rigorous. Rails typically undergo:

- Tensile testing

- Impact testing

- Falling weight testing

- Visual and dimensional inspection

Each rail is traceable, with identifying marks rolled or stamped into the product to record manufacturing details and ensure quality control.

Why does rail manufacturing quality matter?

The rail manufacturing process directly influences:

- Track safety

- Asset life

- Maintenance costs

- Long‑term network performance

Understanding how rail is made helps engineers, maintainers, and asset managers make better decisions across the rail lifecycle, from design and procurement through to inspection and renewal.

At Inform Rail, we focus on improving rail outcomes through engineering knowledge, practical experience and a deep understanding of how rail infrastructure performs in the real world.

More Posts

DIN vs AS vs JIS Rail Profiles: What are they?

When sourcing crane rail for industrial applications, whether for overhead cranes, port terminals or fabrication yards, understanding where your rail is made is essential. The origin of your rail affects not only quality and compliance but also availability, lead times and long-term performance.