Services

Strong Rail Solutions in 2026

Let us help with your crane rail, crane rail clips, pads, fishplates, sole plates and more.

Inform Rail Services

Using our engineering knowledge and rail experience, Inform Rail know how to provide a range of products to meet the tough demands of any project.

- rail size

- rail clips and spacing

- rail pad

- bolts and nuts

- fishplates

- sole plates, including dimensions and setup

- size and length of hold down bolts

- corrosion protection

FAQs

Crane rail clips (sometimes called crane rail fixing clips) are used to fasten the crane rail and depending on the application, are generally used with other fastening solutions such as rail pads and fishplates. Rail clips are regarded as efficient fasteners to secure the rail to avoid movement.

Welded rail clips are two part welded adjustable clips. The clip is made up of a clip top and lower weldable forged steel component that interlock, slide and tighten together.

The clips are designed and perform as friction connections and must be tightened to the prescribed torque. The clip top is supplied with a vulcanized synthetic pressure block.

Through bolt crane rail clips are a single bolt adjustable crane rail clip that features a circular cam that locks the clip into position against the rail. The clip is designed and performs as a bearing connection.

When the rubber pressure block needs to be replaced on the rail clips, only the rubber component is replaced and not the entire clip top.

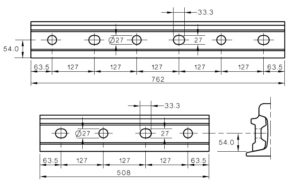

Fishplates (sometimes referred to as joint bars) are used to join the ends of rail lengths together. Fishplates are rectangular bars with one on each side of the two joining rails as part of a set.

Fishplates are commonly 4-hole or 6-hole configurations, through which two rails are bolted together to create a continuous track. Inform Rail can supply the bolts, nuts and washers to complete the connection.

Crane rail pads are for use with lighter crane wheel loading and reduces:

- noise and structural vibration

- rail wear and fatigue

- crane runway maintenance

- stress in the runway structure and the crane

The rail pads are resistant to water, oil, grease, mildew and fungus and can absorb the uneven contact between the rail and the supporting structure.

Crane rail pads eliminate wear grooving of the rail on the runway due to fretting corrosion and distributes the wheel load over a larger surface are.

More information on Grade 8.8 can be found in one of Hobson Engineering newsletters.