What really matters when choosing or replacing rail clips

At Inform Rail, we regularly review drawings that specify an existing rail clip for crane rail, a rail clip that’s no longer manufactured, or the two classic words: “or equivalent.”

But what does it really mean for you when pricing a project, replacing rail clips or designing a new crane rail system?

Let’s break it down.

What Brands of Crane Rail Clips Exist?

Today, most manufacturing occurs in China and Malaysia and these rail clips, and other brands on the market, are engineered to:

- Secure crane rails to their support structure

- Allow controlled lateral movement caused by thermal expansion, wheel forces or operational loads

- Reduce wear and extend the life of the overall rail system

While Grantrex, Gantrail, Molyneux and Bemo are commonly known, numerous other manufacturers produce clips with similar form, function and load performance.

Regardless of brand, the primary purpose remains the same:

Hold the rail securely while allowing movement and reducing stress on the rail and structure.

How to Verify the Clips You Have

Most crane rail clips, no matter the manufacturer, include identifying marks, often stamped or cast, such as:

- The manufacturer’s name or logo

- A model or series number

These markings are usually found on the cam or body of the clip.

For accurate comparison or replacement, product data sheets remain the most reliable source for:

- Load capacity

- Material specifications

- Installation requirements

- Performance characteristics

We have an extensive archive of historical product data sheets, enabling us to assist with identifying older or discontinued clip types.

Replacing Existing Clips: Should You Use the Same Ones?

Not always.

While replacing your clips with identical models might feel like the simplest choice, it may not be the best or most compliant one.

Your current installation may:

- No longer meet modern design standards

- Have been originally built with non-optimised components

- Use clips that are now obsolete or outperformed by newer designs

Before replacing any clips, it’s important to review:

- Original design intent – does it still apply to current operations?

- Changes in operational load or crane frequency

- Rail alignment issues or new wear patterns

- Why the existing clips failed or wore out

Updated product alternatives may offer better:

- Load performance

- Adjustment capability

- Installation efficiency

- Long-term durability

Giving Inform Rail a call, engaging an engineer or reviewing the original design documentation helps to ensure replacement clips are fit for purpose and align with current standards and site conditions.

More Posts

How is rail manufactured? Let’s look at the rail rolling process

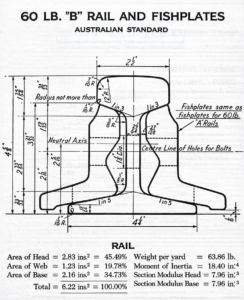

When maintaining or upgrading industrial tracks, slipways, or crane runways, a major challenge is sourcing replacements for rail sections that are no longer manufactured. This includes BHP 60 lb B rail and the later 31 kg rail profile. Both have been out of production for decades, which means operators today need a reliable, modern alternative.

How should I replace BHP 60lb Rail or 31kg Rail?

When maintaining or upgrading industrial tracks, slipways, or crane runways, a major challenge is sourcing replacements for rail sections that are no longer manufactured. This includes BHP 60 lb B rail and the later 31 kg rail profile. Both have been out of production for decades, which means operators today need a reliable, modern alternative.

What is Block Rail?

Block Rail, or flat bar crane rail, is a simple yet essential component in crane rail systems throughout Australia. It supports smooth reliable travel for trolleys and overhead cranes in workshops warehouses and industrial facilities.

Rail Drill: Saved the day for Inform Rail

Just before shipping a rail product, Inform Rail received a last-minute request from a customer: could the rail be drilled before dispatch? Normally, cutting and drilling are handled by trusted partners, but this time there was no time to waste. That’s when the portable rail drill stepped up. The team grabbed the PRO NM-360 Cordless Rail Drilling Machine, and it delivered exactly what was needed—clean, accurate holes in hardened rail, right on schedule.