Crane Rail Clips

Inform Rail supplies high-performance crane rail clips designed for secure, adjustable and long-lasting rail fastening in all environments. Our product range includes weldable crane rail clips and through-bolt rail clips, engineered to meet the demanding specifications of crane rail systems across Australia.

Inform Rail stocks a wide range of crane rail clips in Brisbane, ready to support projects nationwide. Whether you’re upgrading an existing system or installing new crane rails, our clips provide reliable performance and cost-effective solutions.

What Are Crane Rail Clips?

Crane rail clips are essential components used to fasten crane rails to their supporting structure. They ensure the rail remains securely in place while allowing for controlled movement due to thermal expansion or vibration. Properly installed crane rail clips help prevent misalignment, reduce wear, and extend the life of your crane rail system.

At Inform Rail, we supply a wide range of crane rail clips suitable for overhead cranes, gantry cranes, container handling systems, mining operations, port infrastructure, and steel fabrication facilities.

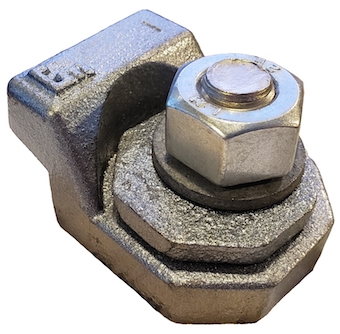

Bolted Rail Clips

Through-bolt crane rail clips offer a robust and cost-effective solution for securing crane rails in industrial environments. Engineered for performance, these clips feature a cam and body that can be hot-dip galvanized without compromising lateral load capacity, as the clip acts as a bearing-type connection. Their design supports standard bolt and nut configurations, simplifying installation and maintenance while ensuring long-term durability and structural integrity.

For detailed information and datasheets, please select a bolted rail clip below

Weldable Rail Clips

Weldable crane rail clips are engineered with a two-part adjustable design, consisting of a clip top and a weldable base that interlock, slide and tighten for precise rail positioning. These clips function as friction connections and must be torqued accurately to ensure optimal performance and safety. The clip top features a vulcanized synthetic pressure block for enhanced grip and vibration resistance. Installation is straightforward, utilising a standard hex bolt and nut configuration.

For detailed information and datasheets, please select a welded rail clip below

Types of Crane Rail Clips We Supply

Inform Rail offers a full selection of adjustable and fixed crane rail clips to suit a wide range of industrial applications. Our product range includes:

- Bolted clips for strong, rigid fastening

- Welded clips for permanent, high-strength installations

- Adjustable clips for precise alignment

- Low-profile clips designed for tight clearance environments

We support compatibility with a broad spectrum of crane rail profiles, including:

- DIN 536 profiles from A45 to A150

- Chinese rail profiles such as 38kg, 43kg, 50kg, 60kg, and 75kg

- Standard rail profiles including 41kg, 50kg, 60kg, and 68kg

- JIS rail profiles

Importantly, Inform Rail is not bound to a single clip manufacturer, allowing us to source and supply the most suitable clip solutions for your specific project requirements, ensuring flexibility, performance and cost-efficiency.

Crane Rail Clips FAQs

Using the right crane rail clips is critical to the safety and efficiency of your crane system. Poorly secured rails can lead to misalignment, excessive wear and even operational failure. Our clips are designed to withstand high loads and forces, allow for movement without compromising stability, minimise vibration and noise, and simplify installation and maintenance.

Crane rail clips are used in a wide range of industries and applications where rail-mounted cranes operate. Common environments include:

- Ports and Container Terminals: For securing rails used by gantry cranes.

- Steel Plants and Foundries: Where high-load cranes are used for material handling.

- Shipyards: For cranes involved in shipbuilding and repair.

- Industrial Facilities: Such as warehouses and manufacturing plants with overhead or gantry crane systems.

Their versatility and reliability make crane rail clips an essential component in any crane operation.

The spacing of crane rail clips depends on several factors, including the type of rail, the expected load, and the specific design of the clip. Proper spacing is critical to ensuring rail stability, minimising wear, and maintaining alignment. While it varies for each application, typical spacing is 600mm but can range from 400 mm to 1,000 mm.

It is important to consult with a qualified engineer to determine the optimal spacing for your specific application.

Yes, many modern crane rail clips are designed for top-down installation. This feature simplifies the installation process, reduces the need for specialised tools, and minimises downtime during maintenance or replacement. Top-down installation is particularly beneficial in environments where access to the underside of the rail is limited or impractical.

Choosing between bolted and welded crane rail clips depends on your specific application and operational needs:

- Bolted Clips: These are ideal for installations where adjustability or temporary setups are required. They are commonly used in environments where the rail alignment may need to be adjusted over time or where the crane system is not permanent.

- Welded Clips: These are better suited for high-load, permanent installations, such as steel mills, shipyards, or heavy industrial facilities. Welded clips provide a stronger and more secure connection, making them ideal for environments with high vibration or heavy-duty operations.

Consider factors such as load capacity, frequency of use, and the need for future adjustments when making your decision.

Crane rail clips are typically manufactured from high-strength materials to ensure durability and reliability in demanding environments. Common materials include:

- Ductile Iron: Known for its toughness and resistance to wear and tear.

- Cast Steel: Offers excellent strength and durability, making it suitable for heavy-duty applications.

- Carbon or Low-Alloy Steel: These materials provide a balance of strength, flexibility, and corrosion resistance, making them ideal for a wide range of industrial applications.

The choice of material often depends on the specific operational requirements, including load capacity, environmental conditions and expected wear.

Crane rail clips are designed to handle lateral loads, ensuring the stability and safety of crane operations. Heavy-duty crane rail clips can typically withstand lateral loads ranging from 40 kN to 55 kN per wheel, depending on the model, material and installation method.

It’s essential to select clips with a load capacity that matches or exceeds the operational demands of your crane system to ensure long-term performance and safety.

Yes, regular maintenance is essential to ensure the longevity and performance of crane rail clips.

- Bolted Clips: These may require periodic tightening and inspection to ensure they remain secure, especially in high-vibration environments.

- Welded Clips: While often more permanent, welded clips should still be checked regularly for signs of fatigue, corrosion, or wear, particularly in high-frequency or heavy-load operations.

Routine maintenance helps identify potential issues early, reducing the risk of system failure and costly downtime.

Yes, rubber pads are often used in conjunction with crane rail clips. These pads are placed beneath the rail to:

- Absorb impact and reduce vibration caused by crane movement.

- Minimise noise levels in the operating environment.

- Protect the rail and clips from excessive wear, extending their lifespan.

Rubber pads are particularly beneficial in high-frequency or heavy-load operations, where vibration and impact are more pronounced.

- Our adjustable crane rail clips ensure accurate rail positioning to meet strict installation tolerances.

- Choose from weldable clips for permanent fastening or through-bolt clips for flexible installation and maintenance.

- Clip bodies and cams can be hot-dip galvanized without compromising lateral resistance, maintaining integrity and corrosion protection.

- Unlike conventional clips, our clip tops feature a modular design that allows for easy replacement of the rubber pressure block, so there is no need to replace the entire assembly.

Looking for reliable crane rail clips in Australia? Contact Inform Rail today for expert advice, fast quotes and premium crane rail fastening solutions. Whether you are in mining, logistics, manufacturing, or infrastructure, we have the clips and service to support your success.