How should I replace BHP 60lb Rail or 31kg Rail?

When maintaining or upgrading industrial tracks, slipways, or crane runways, a major challenge is sourcing replacements for rail sections that are no longer manufactured. This includes BHP 60 lb B rail and the later 31 kg rail profile. Both have been out of production for decades, which means operators today need a reliable, modern alternative.

At Inform Rail, we supply 37 kg rail as the practical, high‑strength replacement for both 31 kg and BHP 60 lb rail, because it delivers dependable performance with ongoing availability.

History of the 31 kg Rail Profile

The 31 kg rail profile has one of the longest continuous histories in Australian rail standards. It was first introduced in 1928 and later converted to metric measurement. It is the only rail section in the current Standard that can be traced back to the A.S. 1916 set, which reflects its durability and widespread historical use.

This rail profile first appeared in AS E.22—1928, where it was designated the 60B profile. It continued to feature in later editions, including the 1937 Standard, again as 60B. In the 1949 and 1964 editions, it was reissued as the 63 lb rail. When Australia moved to metric rail specifications, the 31 kg profile was incorporated into the updated Standard and appeared in the 1977, 1985, 1990, 1995, 2000 and 2002 editions. Its repeated inclusion shows how widely it was used across multiple generations of rail installation and maintenance practices.

Despite its long service life, both 31 kg and BHP 60 lb rail have been out of production for many years, and no mill rolls them today. Operators relying on these sections must turn to second‑hand supply, which is unpredictable and inconsistent.

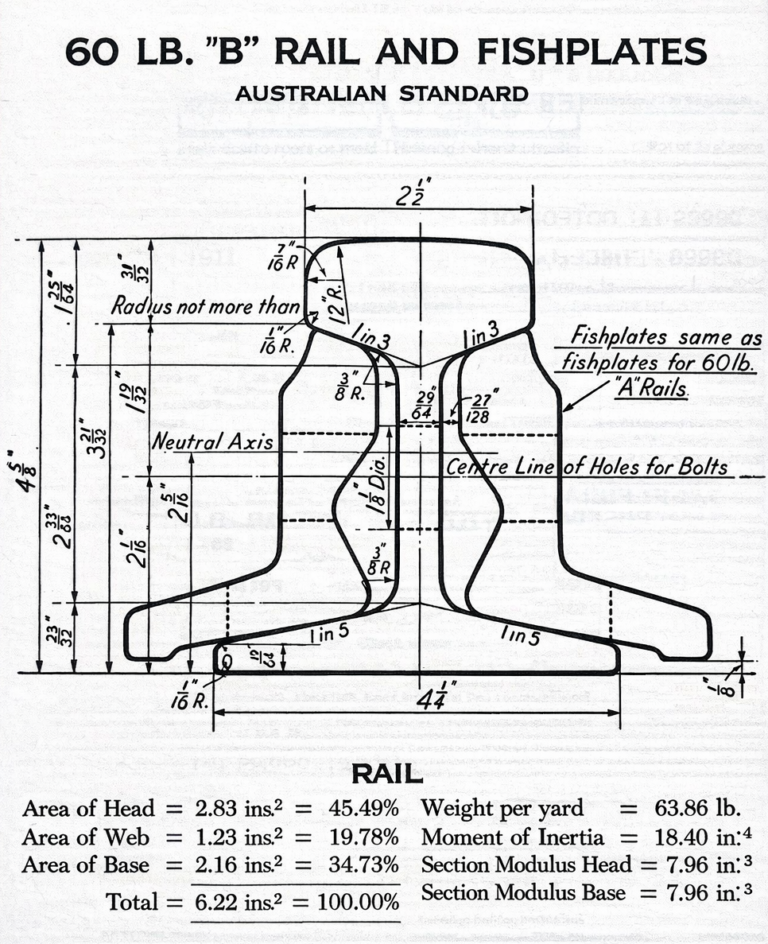

Understanding the Obsolete Rail Profiles

| Specification | 31 kg (AS 1085.1-2002) | BHP 60 lb B | 37 kg (JIS 37A) |

|---|---|---|---|

| Calculated mass | 31.5 kg per metre | 63.36 lb per yard | 37.2 kg per metre |

| Rail height | 117.5 mm | 117.5 mm (4 & 5/8 inches) | 122.24 mm |

| Head width | 63.5 mm | 63.5 mm (2 & 1/2 inches) | 62.71 mm |

| Base width | 108.0 mm | 108.0 mm (4 & 1/4 inches) | 122.24 mm |

37 kg Rail as the modern replacement

Why is 37 kg a good match for both 31 kg and BHP 60 lb?

The 37 kg profile provides close dimensional alignment with both historic sections. Its head width is almost identical to the head width of 31 kg and BHP 60 lb and its rail height sits only a few millimetres above both profiles. This allows smooth transitions and makes it a practical replacement for rail systems originally built around these now‑obsolete sections.

Readily available in Australia

Availability is one of the strongest advantages. While 31 kg and 60 lb rails are only obtainable through second‑hand channels, 37 kg rail continues to be rolled internationally and stocked locally, which provides a reliable source for maintenance and new installations.

Compatible with modern engineering and fastening systems

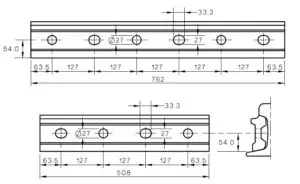

The modern JIS specification also ensures compatibility with today’s fastening systems, welding processes and industrial design standards. This removes the need for custom fabrication, fishplates, or special machining that older BHP sections often require.

Why choose Inform Rail?

Inform Rail is ideally positioned to support operators who are replacing obsolete rail profiles. We understand the full range of historic BHP sections, including 31 kg, 40 lb, 41 lb, 50 lb and 60 lb, which allows us to recommend the correct modern alternatives. We work with reputable mills and suppliers and offer fishplates, drilling patterns, custom lengths, rail clips and sole plates.

More Posts

So, what are fishplates?

Fishplates, also known as rail joints or joint bars, are steel components used to connect two rail sections end-to-end. They are bolted to the sides of the rail web and serve several important functions in crane rail and railway systems.

Melbourne Tram Rail: A legacy of local industry and global change

When sourcing crane rail for industrial applications, whether for overhead cranes, port terminals or fabrication yards, understanding where your rail is made is essential. The origin of your rail affects not only quality and compliance but also availability, lead times and long-term performance.

Whyalla’s Origins: Building Australia’s Rail Capacity

Whyalla has long stood at the centre of Australia’s rail infrastructure story. From its early days under BHP to its current role as the nation’s only domestic producer of steel rail, Whyalla’s contribution to crane & rail systems is unmatched in scale, quality, and strategic importance.

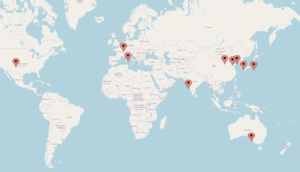

Where Is My Rail Made? A Global Guide to Crane Rail Manufacturing

When sourcing crane rail for industrial applications, whether for overhead cranes, port terminals or fabrication yards, understanding where your rail is made is essential. The origin of your rail affects not only quality and compliance but also availability, lead times and long-term performance.