DIN vs AS vs JIS Rail Profiles: What are they?

Choosing the right rail profile for your crane system is critical to ensuring long-term performance, safety, and compliance. In Australia, three major standards dominate the conversation: DIN (Germany), AS (Australia), and JIS (Japan). Each has unique characteristics, and the right choice depends on your application, environment, and sourcing strategy.

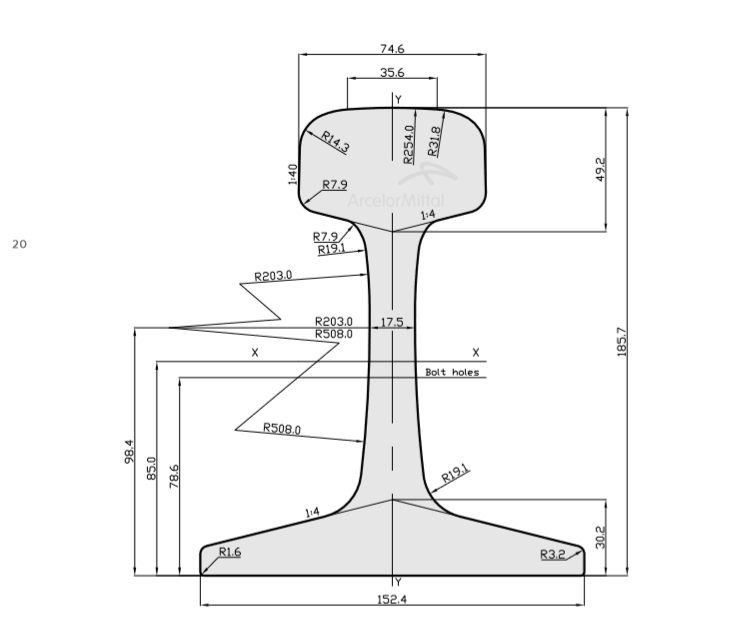

DIN Rail Profiles (DIN 536)

Origin: German Institute for Standardization

Common Types: A45, A55, A65, A75, A100, A120 & A150

Applications:

- Widely used in overhead crane runways, port terminals, and heavy industrial settings

- Known for high load capacity

Advantages:

- Excellent for high-speed, high-load crane systems

- Compatible with adjustable clip systems

- Global availability

Considerations:

- Imported rails can have longer lead times

AS Rail Profiles (Australian Standard)

Origin: Standards Australia

Common Types: 41kg, 47kg, 50kg, 53kg, 60kg, 68kg

Applications:

- Used extensively in mining, freight, and crane rail systems across Australia

- Manufactured in Whyalla, Australia’s only domestic rail producer

Advantages:

- Locally available with shorter lead times

- Designed for Australian conditions including extreme temperatures and heavy haul operations

- Proven performance in head-hardened applications for fatigue resistance

JIS Rail Profiles

Origin: Japanese Industrial Standards

Common Types: 6kg to 30kg (light rail)

Applications:

- Common in light rail, crane rail systems and tramways across Asia

Advantages:

- High-quality steel with uniform hardness across the rail

- Suitable for light-duty cranes and automated systems

Considerations:

- Less common in Australia and may require special ordering

- Not ideal for heavy-duty or mining applications

Which Is Right for Your Crane?

| Criteria | DIN | AS | JIS |

| Heavy Load Capacity | ✓ | ✓ | – |

| Local Availability in Australia | – | ✓ | – |

| Precision Alignment | ✓ | ✓ | ✓ |

| Fatigue Resistance | ✓ | ✓ | ✓ |

| Best for Light-Duty Cranes | – | – | ✓ |

Final Recommendation

If you’re operating in Australia and need reliable, compliant, and locally available crane rail, AS rail profiles from Whyalla are the most practical and strategic choice. They are the only rail profiles manufactured domestically, ensuring supply chain security and alignment with Australian standards.

For specialised applications or international projects, DIN profiles offer engineering precision and global compatibility, while JIS profiles are best suited for light-duty or automated crane systems.

More Posts

Rail Drill: Saved the day for Inform Rail

Just before shipping a rail product, Inform Rail received a last-minute request from a customer: could the rail be drilled before dispatch? Normally, cutting and drilling are handled by trusted partners, but this time there was no time to waste. That’s when the portable rail drill stepped up. The team grabbed the PRO NM-360 Cordless Rail Drilling Machine, and it delivered exactly what was needed—clean, accurate holes in hardened rail, right on schedule.

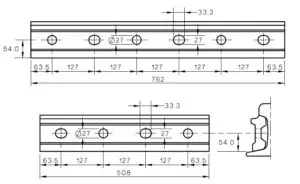

So, what are fishplates?

Fishplates, also known as rail joints or joint bars, are steel components used to connect two rail sections end-to-end. They are bolted to the sides of the rail web and serve several important functions in crane rail and railway systems.

Melbourne Tram Rail: A legacy of local industry and global change

When sourcing crane rail for industrial applications, whether for overhead cranes, port terminals or fabrication yards, understanding where your rail is made is essential. The origin of your rail affects not only quality and compliance but also availability, lead times and long-term performance.

Whyalla’s Origins: Building Australia’s Rail Capacity

Whyalla has long stood at the centre of Australia’s rail infrastructure story. From its early days under BHP to its current role as the nation’s only domestic producer of steel rail, Whyalla’s contribution to crane & rail systems is unmatched in scale, quality, and strategic importance.