Melbourne Tram Rail: A legacy of local industry and global change

Melbourne’s tram network is the largest operational urban tramway in the world, and its rails have a rich history that reflects the broader story of Australia’s industrial development. From local manufacturing to imported steel to the rise and fall of local grooved rail production, the evolution of tram rail in Melbourne is a testament to both innovation and adaptation.

The Early Days: Imported Rails for a Growing Network

When electric tramways were introduced to Australia in the late 19th century, the local steel industry was still in its infancy. As a result, tram rails, like railway line, had to be imported, often from Europe. This included grooved rail, a specialised profile designed to accommodate tram wheels while allowing for a flush surface with the road, essential for street-running trams.

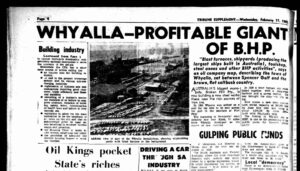

The Hawthorn Tramways Trust (HTT), one of Melbourne’s early tram operators, was a strong advocate for local manufacturing. In the early 20th century, the HTT approached BHP to supply grooved rail for its new Burwood and Wattle Park lines. However, BHP declined the request. The company determined that the cost of machining grooved rail was too high for the relatively small quantities required, especially during wartime when freight and insurance costs were already elevated. As a result, the HTT was forced to continue importing rail.

Local Production Begins: BHP and the Newcastle Steelworks

It wasn’t until the establishment of the BHP Newcastle steelworks in 1915 that Australia gained the capacity to roll rail in significant quantities. This marked a turning point for the local rail industry, enabling domestic production of standard rail profiles for both railway and tramway use.

Eventually, BHP did begin producing grooved tram rail, supporting the expansion and maintenance of Melbourne’s tram network. However, this local supply was short-lived.

The decline of Tram Rail Manufacturing in Australia

By the 1950s and 1960s, tram systems across Australia were in decline. Cities like Sydney, Adelaide, and Brisbane dismantled their networks in favour of buses and cars. As the national demand for tram infrastructure shrank, so too did the market for grooved rail.

Recognising the diminishing commercial viability, BHP made the decision to cease production of grooved tramway rail. The final order was placed in 1970 by the Melbourne and Metropolitan Tramways Board (M&MTB) and the State Electricity Commission of Victoria (SECV). When the Bendigo and Ballarat tram systems closed, the M&MTB acquired the remaining unused grooved rail stock from the SECV to support Melbourne’s ongoing tram operations.

Legacy and Preservation

Despite the end of local grooved rail production, Melbourne’s tram network not only survived but thrived. Today, it remains a vital part of the city’s public transport system and a symbol of its urban identity. The legacy of BHP’s involvement in tram rail production is preserved in historical records and in the very tracks that still carry trams through Melbourne’s streets.

Organisations like the Hawthorn Tram Depot Museum continue to document and celebrate this history, ensuring that the story of Melbourne’s tram rail, and the industries that supported it, is not forgotten.

Conclusion

The story of Melbourne tram rail is more than just a tale of steel and infrastructure. It reflects the broader shifts in Australian industry, transportation policy and urban development. From imported beginnings to local innovation and eventual consolidation, the evolution of tram rail in Melbourne is a unique chapter in the nation’s engineering heritage.

More Posts

Rail Drill: Saved the day for Inform Rail

Just before shipping a rail product, Inform Rail received a last-minute request from a customer: could the rail be drilled before dispatch? Normally, cutting and drilling are handled by trusted partners, but this time there was no time to waste. That’s when the portable rail drill stepped up. The team grabbed the PRO NM-360 Cordless Rail Drilling Machine, and it delivered exactly what was needed—clean, accurate holes in hardened rail, right on schedule.

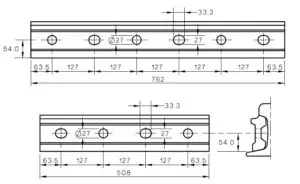

So, what are fishplates?

Fishplates, also known as rail joints or joint bars, are steel components used to connect two rail sections end-to-end. They are bolted to the sides of the rail web and serve several important functions in crane rail and railway systems.

Whyalla’s Origins: Building Australia’s Rail Capacity

Whyalla has long stood at the centre of Australia’s rail infrastructure story. From its early days under BHP to its current role as the nation’s only domestic producer of steel rail, Whyalla’s contribution to crane & rail systems is unmatched in scale, quality, and strategic importance.

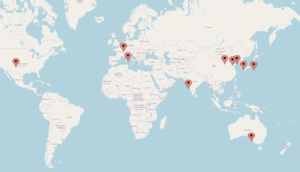

Where Is My Rail Made? A Global Guide to Crane Rail Manufacturing

When sourcing crane rail for industrial applications, whether for overhead cranes, port terminals or fabrication yards, understanding where your rail is made is essential. The origin of your rail affects not only quality and compliance but also availability, lead times and long-term performance.